色残りや樹脂残りを未然に防止

高い洗浄力と抜け性の良さを同時に実現

射出成形において、色変えや材料の切り替えは、生産コストや、成形品の品質に大きな影響を与える重要なプロセスです。前材が排出しきれておらず、成形した製品に混入した場合は成形不良となるため、直接生産に関わらないように見えて重要な工程です。

ここでは射出成形における色替えと樹脂替えに対するパージ剤の役割について紹介します。

色替え、樹脂替えに関する射出成形現場の課題

- 共材置換を行い色替えを行っているがショット数が多く、色切り替えに時間がかかっている。生産性を向上したい。

- 同じく共材置換を行っているが、後材のペレットを無駄に多く消費してしまっていると感じている。

- 現在使っている洗浄剤では洗浄力にムラがあると感じている。

- 色が切り替わったように見えるが、ランナーの先に色汚れが存在している。

- 射出成形現場で、さらなる品質改善を求められている。

エコマルは特に洗浄力が強く、

色残りや色汚れに威力を発揮します。

共材置換 VSパージ材

エコマルは特に洗浄力が強く、色残りや色汚れに威力を発揮します。

共材置換 VSパージ材

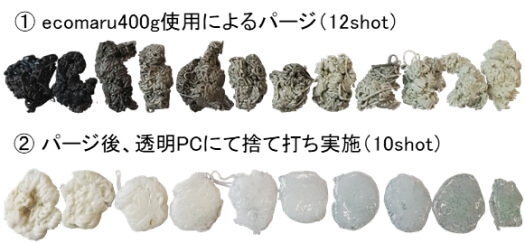

色替えの際のecomaruの洗浄力評価を行いました。PC(ポリカーボネート)を80トンの射出成形機で黒色から透明への色替えです。使用したecomaruは高洗浄タイプのGWSです。結果として共材置換で残っていた黒色がecomaru使用では見られず、廃棄量も36%削減されました。

| 検証条件 | ◇ 樹脂種類:PC ◇ 成型機容量:80トン ◇ グレード :GWS |

| 評価内容 | 色替え【黒 ⇒ 透明】 |

共材置換

置換後成形したところスプルーに黒色発生

- 共材量 : 1100g

- Shot数 : 合計42shot

課題解決事例

| 事例 | 樹脂替え・色替え |

| 検証条件 | ◇ グレード:GWS ◇ 使用樹脂: PP,ABS,POM |

| 実証 | PPからABS、POMからABSなどの樹脂替え及び、黒、赤、青など着色した樹脂から白色の樹脂に色替えの際にパージしている |

| 評価 | 現行のパージ剤と比べ洗浄力が高く、且つ、抜け性がよい |

| 事例 | 色残り問題改善 |

| 検証条件 | ◇ グレード:GWS ◇ 使用樹脂: PA66【黒】 |

| 実証 | 【1】GWSで洗浄後、現(他社)パージ剤で再洗浄実施 →現パージ剤に着色なくきちんとパージ出来ている 【2】現パージ剤で洗浄後、GWSで再洗浄実施 →GWSに着色発生。良くパージしていることを確認 |

| 評価 | 現パージ剤より使用量を減らせる |

メニュー