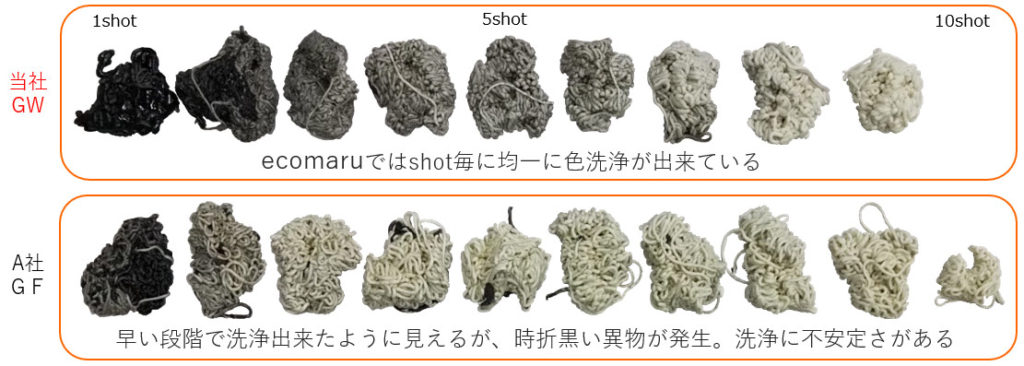

ecomaruは1Shot毎にまんべんなく成形機内の汚れをさらいます。

そのため、パージダンゴは徐々に色が変わっていきます。洗浄性が悪いのではなく、これまでにない洗浄性を実現した新パージ剤の特徴です。

黒点不良の削減効果でご評価してください

初回の洗浄では、従来取れなかったものを洗浄するため、洗浄剤を多く使用します。

ダンゴ数評価の場合、ご注意いただきたいこと

初回洗浄では洗浄剤を多く使用するため、ダンゴ数評価の場合、「取れていない」と錯覚する事があります。パージ色になるまで洗浄し、成形開始後の不良率の変化で評価お願いします。

ここが特徴 PC樹脂「黒色」洗浄

使用上の注意

- ご使用前に必ず安全データシート(SDS)と下記の注意事項をお読みください。

-

使用温度をお守りください。

使用温度範囲を厳守してください。

使用下限温度以下では、過負荷(オーバーロード)にご注意ください。

使用上限温度以上では、ecomaruが分解して着火の可能性があります。また、液状化して飛散による火傷の恐れがあります。 - 洗浄以外の用途使用は行わないでください。

- ecomaruはシリンダー内に滞留させないでください。

- シールには使用しないでください。ガラスが冷え内部で固まる恐れがあります。

- ホットナンナー、コールドランナーの洗浄には適しておりません。ガラスが冷え内部で固まる恐れがあります。

パージ剤排出補足

「GWS」

- AS樹脂を使用しています。AS樹脂は金属との濡れ性が良く、洗浄後は完全に排出しないと成形不良の原因になります。特に後材が透明樹脂の場合は細心の注意が必要です。

- PP・PE(MFR5~10)を2度洗い用として使用していただき、使用する量はパージ剤と同量を目安として、貴社環境下で最適化を図ってください。

- 尚、透明材料への置換の場合、PP・PEはパージ剤使用量の1.5倍が目安となります。