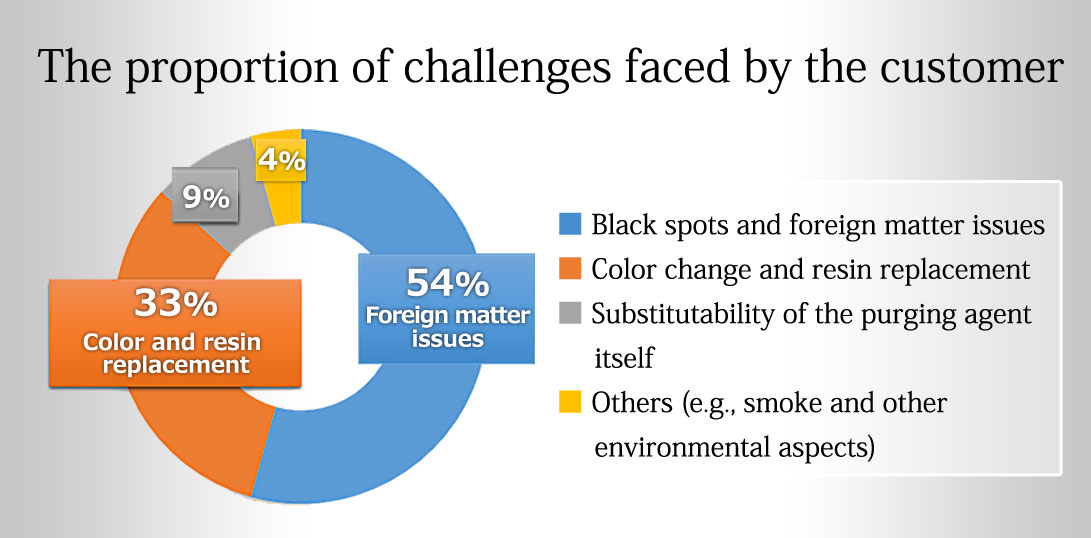

Purging Compound Evaluation – Carbide Removal Edition introduced our recommended method for evaluating Purging Compounds to address foreign matter defect issues. “Foreign matter defect issues” are the most common concern for companies engaged in resin molding. The next most frequently heard issues are related to “color change and resin change” during purging.

*The chart below shows the concerns of our customers at our company (including cases with multiple concerns).

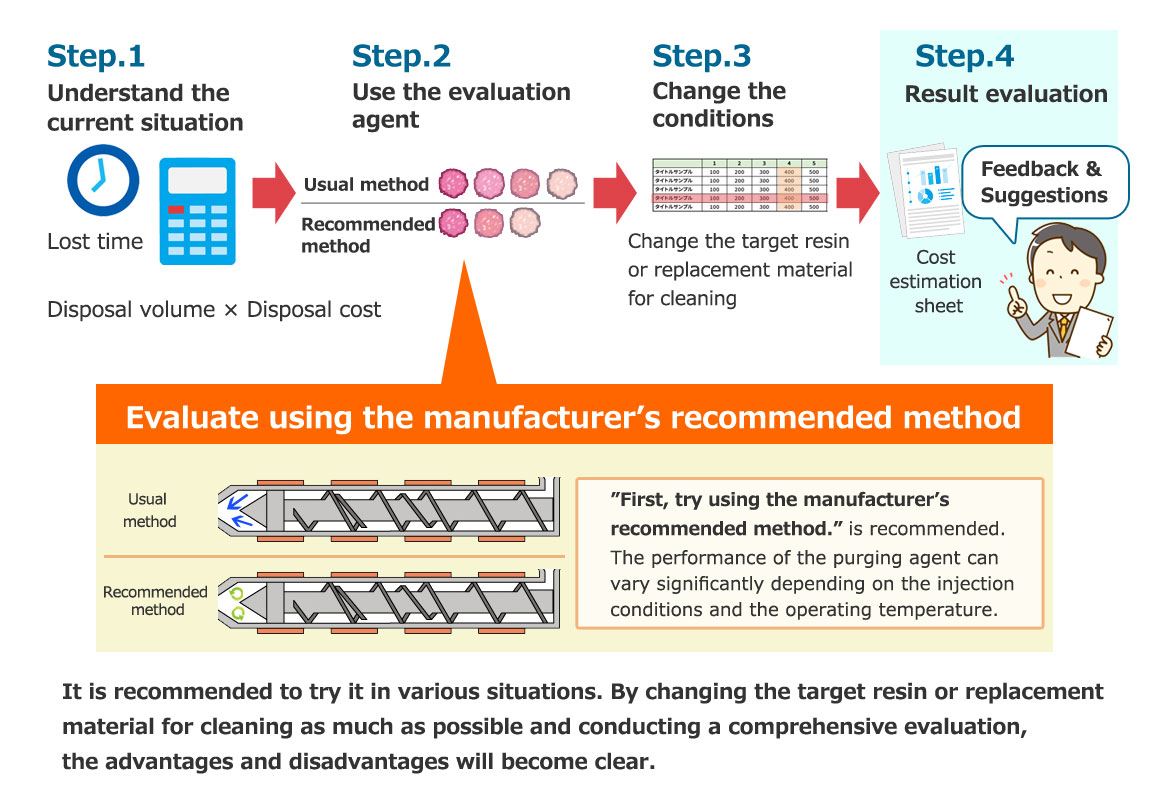

In this article, we will introduce our recommended evaluation method for purging compounds, focusing on their performance in “color change and resin change.”

Introduction to the Evaluation Method

We believe that the evaluation of purging compounds for color change and resin change is simpler compared to comparing foreign matter defects. However, there are still some points we would like our customers to pay closer attention to, which we will introduce step by step.

- It takes a long time for the previous material to be fully purged (the subsequent material purge takes a long time to complete).

- It seems that the material replacement is complete, but foreign material believed to be the previous material is found mixed in during production.

Notes and Additional Information for Each Case

In the initial use, defects may occur frequently, and the amount of purging may be higher. If you are considering Ecomaru, please inform your representative that you do not usually use purging compounds.

Generally, filler-containing (high cleaning power) purging compounds may take longer to be replaced by the subsequent material. Ecomaru is designed with consideration for replacement with subsequent materials, but if you have any concerns, please consult our customer service.