Menu

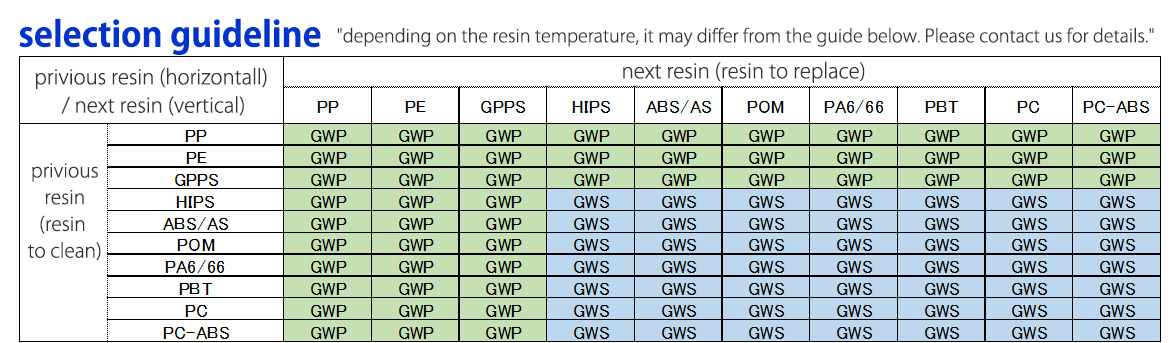

Compatible with a wide range of resins with 2 grades

Can be used in simple conditions at production sites

GWP…Priority on glass discharge, for color change/resin change. High cleaning and excellent subsequent resin replacement property (material: PP + GW)

GWS…Priority on carbide removal. Emphasis on balance for applicable resin and a wide coverage of temperature range (material: AS + GW)

Purging method recommendations: Using both automatic purge and short purge jointly is recommended.

Short purge is a method for repeating “less measurement/weighning” and “high-speed injection”.

- In case of our 80-ton molding machine, for an example, cleaning is done by setting the measurement to 15 mm, and the speed increased from normal 100 msec to 120~150 msec.

- Rotation speed and temperature are set the same as those of molding conditions for the prior material.

- This method is effective for discharging ecomaru by subsequent material as well. Please take a look at here for cleaning method recommendations .

Menu