Premium grade "GSS" now available for the plastic molding machine cleaner "ecomaru"!

Cleaning efficiency 1.25 times

Replacement efficiency 1.25 times

UP

Gentle on equipment

Can suppress wear like GF.

Improvement of Work Environment

Designed to suppress odor and smoke.

SDGs-Compliant Scrap Material

Recycled material 60% used

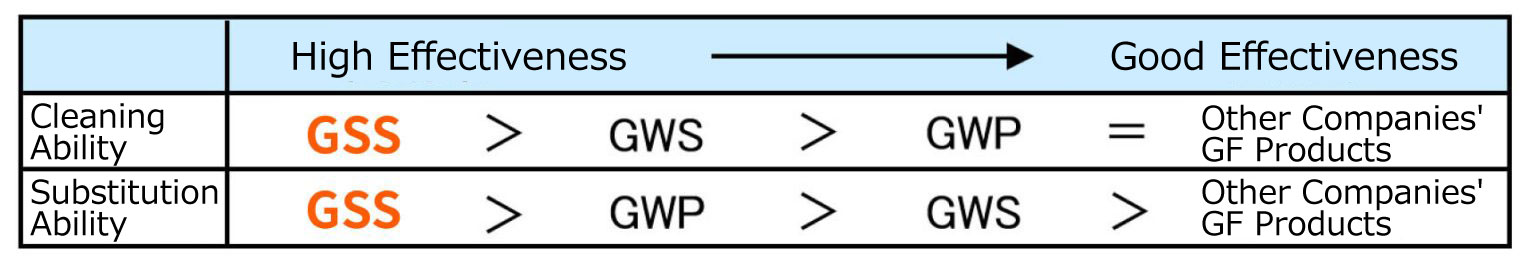

Differences from Conventional Products

Performance Aspects

* Based on our evaluation.

* The comparison with other companies’ GF products is with representative samples. Results may not be consistent across all manufacturers.

| Cleanability: | In addition to the power of glass wool, the power of foaming has created a cleanability that surpasses the GWS grade. |

| Replaceability: | By enhancing the release of the purging compound from the screw barrel, it achieves replaceability surpassing the GWP grade. |

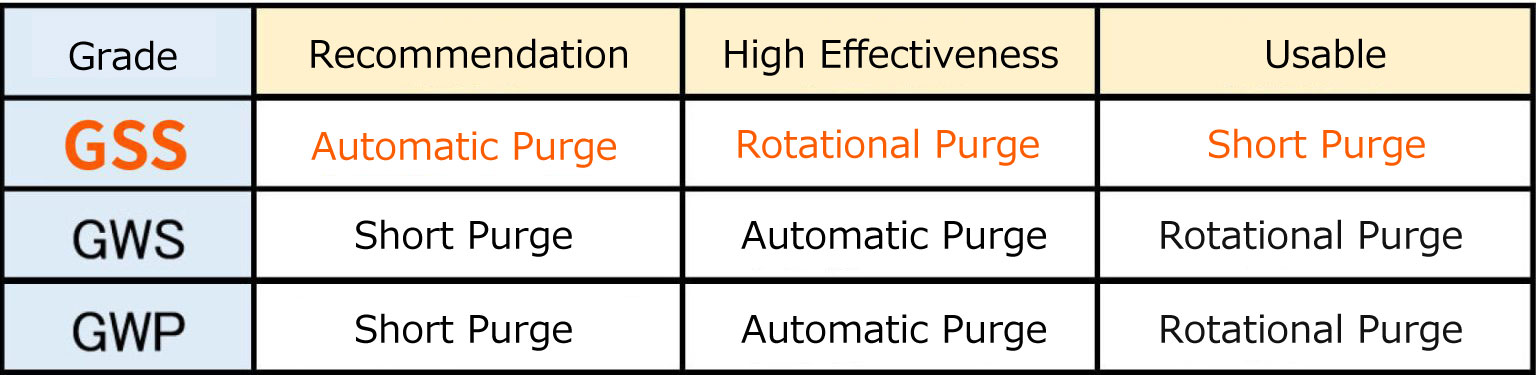

Recommended Purging Method

Short purging is a method that repeatedly uses “less metering” and “high-speed injection.”

- In the case of our 80-ton molding machine, for example, set the metering to 15 mm and increase the speed from the usual 100 mm/sec to 120-150 mm/sec for cleaning.

- The rotation speed and temperature remain as per the molding conditions of the previous material.

- This method is also effective for the discharge of ecomaru by the subsequent material.

| Grade | Features | Materials | Temperature Range | Applicable Resins |

| GSS | High-grade product Carbide removal / Color change / Resin change Combines highest cleaning power with excellent subsequent replacement All-purpose grade |

AS+GW | 200 ~ 330℃ | PC・PC-ABS・PA6T/9T・ABS・AS ・HIPS・PA6/66・POM・PBT・Transparent material |

| GWS | Emphasis on carbide removal Balanced for a wide range of applicable resins and temperature |

AS+GW | 200 ~ 320℃ | PC・PC-ABS・PA6T/9T・ABS・AS ・HIPS・PA6/66・POM・PBT |

| GWP | Emphasis on glass discharge Color change / Resin change High cleaning power with excellent subsequent resin replacement |

PP+GW | 180 ~ 280℃ | ABS・AS・HIPS・PA6/66・POM ・PBT・PP・PE・GPPS・Transparent material |