Menu

Recommended Purging Method

| Grade | Recommended | High Effectiveness | Usable |

|---|---|---|---|

| GSS | Automatic Purge | Rotational Purge | Short Purge |

| GWS | Short Purge | Automatic Purge | Rotational Purge |

| GWP | Short Purge | Automatic Purge | Rotational Purge |

- For example, with our 80-ton molding machine, set the measurement to 15mm and increase the speed from the usual 100mm/sec to 120-150mm/sec for cleaning.

- The rotation speed and temperature remain the same as the molding conditions of the previous material.

- This method is also effective for ejecting ecomaru with subsequent materials.

| Molding Machine Capacity (Clamping Force) | Recommended Usage (kg) |

|---|---|

| 80 tons | 0.2~0.4 |

| 125 tons | 0.4~0.6 |

| 550 tons | 1.5~2.5 |

| 800 tons | 4.0~6.0 |

| 1250 tons | 6.0~8.0 |

| 3000 tons | 15~20 |

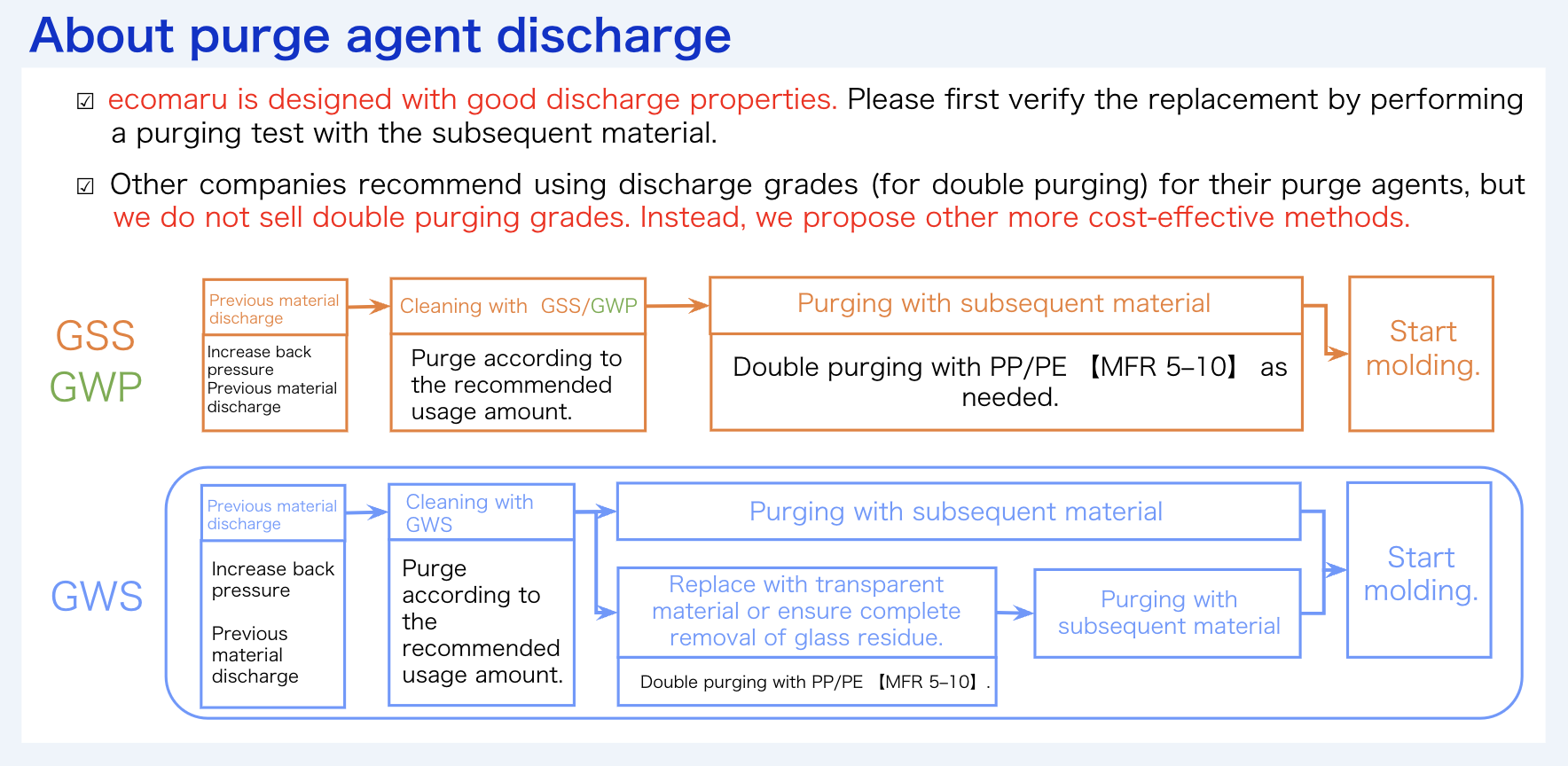

Regarding the discharge of purging compounds

- Other companies recommend using a discharge grade (for double purging), but we do not sell double purging grades and propose other more cost-effective methods.

- After cleaning with ecomaru, perform a discard shot with the subsequent material, or replace it using the following method.

-

"GSS・GWS" uses AS resin.

AS resin has good wettability with metal, and if not completely discharged after cleaning, it can cause molding defects. Special caution is required when the subsequent material is a transparent resin. Use PP (MFR5~10) for double purging, with the same amount as the purging compound as a guideline, and optimize it under your company's conditions. For replacement with transparent materials, 1.5 times the amount of PP compared to the purging compound is recommended. - "GWP" uses PP resin. After cleaning, discharge with low MFR PP or PE.

- For detailed removal methods, please contact us individually.

Supplementary Usage Instructions for Ecomaru by Resin Type

PP, PE systems, PS systems (Olefin resins)

- If the cylinder temperature during molding is below 230°C, increasing it to above 240°C before introducing ecomaru can improve the cleaning effect and glass discharge efficiency.

- When changing colors or resins within olefin resins, we recommend the GWP grade. For carbide countermeasures or addressing MB coloring contamination, we recommend the GSS grade.

ABS Systems

- We recommend cleaning with either the GSS or GWS grade.

POM

- If the cylinder temperature during molding is below 230°C, increasing it to above 240°C before introducing ecomaru can improve the cleaning effect and glass discharge efficiency.

- For color changes or resin changes, we recommend the GWP grade. For carbide countermeasures, we recommend the GSS or GWS grade.

PA6/66

- We recommend cleaning with either the GSS or GWS grade.

PA6T/9T

- If the cylinder temperature during molding is above 330°C, decreasing it to below 330°C before introducing ecomaru can improve the cleaning effect and glass discharge efficiency.

- We recommend cleaning with the GSS grade.

PBT

- We recommend cleaning with either the GSS or GWS grade.

PC

- We recommend cleaning with the GSS grade if the cylinder temperature during molding is around 300°C.

- If it is below 280°C, we recommend cleaning with either the GSS or GWS grade.

Automatic Purging Method for Injection Molding Machines

Discharge of Previous Resin

- Raise the back pressure to discharge the resin.

- Clean the hopper.

Preparation

- Can be handled at the pre-resin processing temperature within the usable temperature range.

- Remove the nozzle from the mold.

Insert ecomaru.

- Insert the recommended amount of purge material and perform purging. *Refer to usage guidelines.

- Visually check and adjust the resin discharge color.

Injection purge

- Increasing the injection speed enhances the cleaning effect.

Inject the resin afterward

- After cleaning, it is recommended to use glass discharge agents, etc., to remove glass fibers.

- Insert the subsequent material and start molding after confirming that ecomaru has been discharged.

Precautions for use

Handling Precautions

- Please refer to the Safety Data Sheet (SDS) before use.

- Wear protective gloves and safety glasses during work.

- This product is flammable, so keep it away from ignition sources during handling and storage.

- Ensure adequate ventilation as gas is generated during cleaning.

- If clogging occurs in the nozzle, etc., during cleaning, immediately turn off the power and consult with the machine manufacturer for appropriate action.

- High-temperature molten resin poses a burn risk, so do not touch it directly.

- Clean up spilled pellets immediately as they pose a slipping hazard if left on the floor.

- Do not mix with other resins.

- Store away from direct sunlight, water leakage, and humidity.

- Dispose of properly in accordance with relevant regulations.

Regarding Usage

-

Please adhere to the usage temperature.

Strictly observe the usable temperature range.

Be cautious of overload below the lower limit temperature.

Above the upper limit temperature, ecomaru may decompose and pose a fire hazard. Additionally, there is a risk of burns due to liquefaction and scattering. - Do not use for purposes other than cleaning.

- Do not leave ecomaru in the cylinder.

- Do not use for sealing. Glass may cool and solidify inside.

- Not suitable for cleaning hot runners or cold runners. Glass may cool and solidify inside.

Menu