Preventing color stains before happens

Achieving high detergency and good removal property at the same time

For injection molding, color change and material switching are important processes having great impacts on production cost and quality of molding products. Causing molding defects If the prior material is not completely discharged and is mixing in the molding product. As such, those processes are critical and important, although those are considered not directly associated with production.

Introducing the roles of purging pellet for color change and resin change for injection molding here.

Issues for color change and resin change at injection molding production sites

- It is taking time to switch the color due to larger number of shots happening when the color is changed by replacing the common material. Wish to improve our productivity.

- Replacing the co-material as well, however, feeling a lot of pellets for the subsequent material are using wastefully.

- Feeling the current purging compounds using have uneven detergency.

- It looks like the color have changed, however there are color stains at the tip of runner.

- Quality improvements are required further at injection molding production sites.

ecomaru has particularly strong detergency,

It is effective for color residues and color stains .

Co-material replacement VS purging material

ekomaru has particularly strong detergency and is effective against color residue and color stains .

Co-material replacement VS purging material

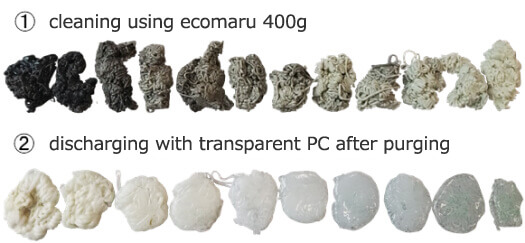

Evaluated the detergency of ecomaru for the color change. The color change from black to transparent for PC (polycarbonate) by 80-ton injection molding machine. High-cleaning type GWS ecomaru was used. The result was the black color was not seen and not identified at all, whereas it was clearly remained and identified after the replacement of co-materials, and the amount of waste was reduced by 36%.

| Verification conditions | ◇ Resin type: PC ◇ Molding machine capacity: 80 tons ◇ Grade: GWS |

| Evaluation contents | Color change [black ⇒ transparent] |

Co-material replacement

When molded after replacement, black color appears on the sprue

- Co-material amount: 1100g

- Number of Shots: 42 in total

Purge pellet ecomaru

No color stains can be seen and identified

- Co-material amount: 400g

- Post-material amount: 300g

- Number of Shots: 22 in total

Problem-solving cases

| Case study | Resin change / color change |

| Verification conditions | ◇ Grade: GWS ◇ Resin used: PP, ABS, POM |

| Verification | Purging is done when changing resins from PP to ABS, from POM to ABS, etc. and for changing colored resins like black, red, blue, etc. to white resins. |

| evaluation | Higher detergency and superior release property than those of current purging compounds |

| Case study | Improvement on color remaining problem |

| Verification conditions | ◇ Grade: GWS ◇ Resin used: PA66 [Black] |

| Verification | [1] After cleaning by GWS, re-cleaning by the current (other company's) purging compound → The purging was completed properly without any coloring on the current purging compound. [2] After cleaning by the current purging compound, re-cleaning by GWS → Coloring occurs on GWS. Purging was done well. |

| evaluation | The usage amount can be reduced compared to that of the current purging compound. |