What is POM?

Polyacetal (POM) resin is a highly crystalline resin with excellent fatigue resistance. It is a material used in a wide range of products, notable for its low coefficient of friction and self-lubricating properties, making it particularly outstanding in friction resistance.

POM is suitable for long-term use in products because it possesses fatigue resistance, allowing it to withstand damage from repeated long-term operations. On the other hand, with an oxidation index of 15, it is a highly flammable material among plastics (flammable = prone to carbonization due to thermal degradation during molding). Many sites report issues with black dot defects in POM.

Black Dot Defect Issue in POM (Polyacetal)

As a solution case, we will introduce an example utilizing purge agent ecomaru.

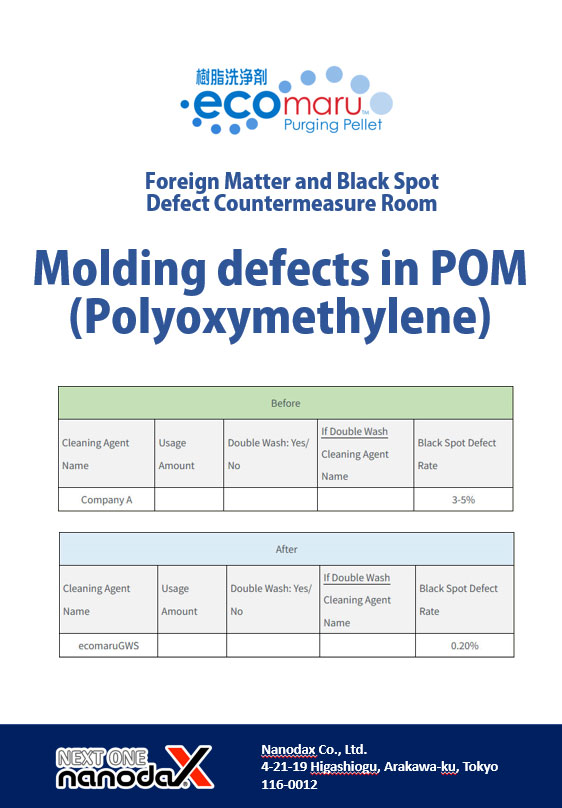

[Case Study]

- The following week after producing POM, there was a particularly high rate of foreign matter defects, which was a significant concern.

- Despite various attempts with different purging compounds, significant results were not achieved.

お客様評価

エコマルを使い始めたところ異物不良が5%から0.2%まで減少し、歩留まりを改善できたため、非常に満足している。

Customer Evaluation

After starting to use ecomaru, the foreign matter defect rate decreased from 5% to 0.2%, improving the yield, which has led to a high level of satisfaction.

| Before | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Purging Compound Name | Usage Amount | Double Wash: Yes/No | If Double Wash

Purging Compound Name | Black Dot Defect Rate | |||||

| Company A | 3-5% | ||||||||

| After | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Purging Compound Name | Usage Amount | Double Wash: Yes/No | If Double Wash

Purging Compound Name | Black Dot Defect Rate | |||||

| ecomaruGWS | 0.20% | ||||||||

POM (Polyacetal) Characteristics

Advantages

- Excellent mechanical strength

- Good wear resistance and sliding properties

- Good dimensional stability

- Low water absorption

- Excellent solvent resistance

- Excellent electrical properties

- Relatively high continuous use temperature

Weaknesses

- Poor weather resistance

- Poor adhesion (No suitable adhesive for POM)

- Susceptible to strong acids

- Flammable

- No transparent products

Manufacturer

| Manufacturer | Product name | |

|---|---|---|

| Asahi Kasei Chemicals Corporation | Tenac | |

| Intertech Corporation | ECOTAL | |

| DuPont Co., Ltd. | Delrin | |

| Toray International, Inc. | Kocetal | |

| BASF Japan Ltd. | Ultraform | |

| Polyplastics Co., Ltd. | DURACON | |

| Mitsubishi Engineering-Plastics Corporation | Iupital | |

Main applications

Often used as a substitute for metal parts.

[Sliding properties, wear resistance, fatigue resistance, high strength]

Gears, bearings, bushings, cams, switches, pulleys, etc.

[High mechanical strength]

Door handles, piping fitting parts, etc.

[Solvent resistance]

Oil tank parts, aerosol valves, etc.

[Others]

Various parts of general machinery, fasteners, building materials such as door rollers, etc.