What is PP (Polypropylene)?

The discovery of the Ziegler-Natta catalyst by German chemist Karl Ziegler marks the beginning of PP (Polypropylene). In 1954, Italian chemist Giulio Natta, in collaboration with Montecatini, first polymerized propylene monomer using a Ziegler-type catalyst. Natta elucidated that this polymer had a regular molecular arrangement and crystalline structure, and he named it isotactic polypropylene. This was the start of PP. Incidentally, Karl Ziegler received the Nobel Prize in Chemistry in 1963.

Polypropylene is a polymer consisting of carbon and hydrogen and is a type of general-purpose resin. Polypropylene is classified into three types in the form of copolymers (mainly with ethylene).

Homopolymer

A homopolymer is a polymer made solely from propylene.

Random Copolymer

A random copolymer contains ethylene typically at a proportion of 4.5% by weight or less within the copolymer.

Block Copolymer

A block copolymer is a composition containing ethylene-propylene polymers, where ethylene is copolymerized in a subsequent reactor following the polymerization of the homopolymer.

It is primarily used in common household items, general merchandise, and packaging materials. Among general-purpose resins, polypropylene has the second highest production volume after polyethylene and is utilized in a wide range of applications.

Black dot defect issue in polypropylene

There is no purging compound specialized for olefin-based resins, and we often hear concerns such as “even if the cleaning performance is good, the replaceability is poor” or “those with good replaceability have inferior cleaning performance.” ecomaru GWP is a purging compound that exhibits excellent effects on olefin-based resins. As a solution for unresolved black dot defects and replacement issues after cleaning, we will introduce an example utilizing purge agent ecomaru.

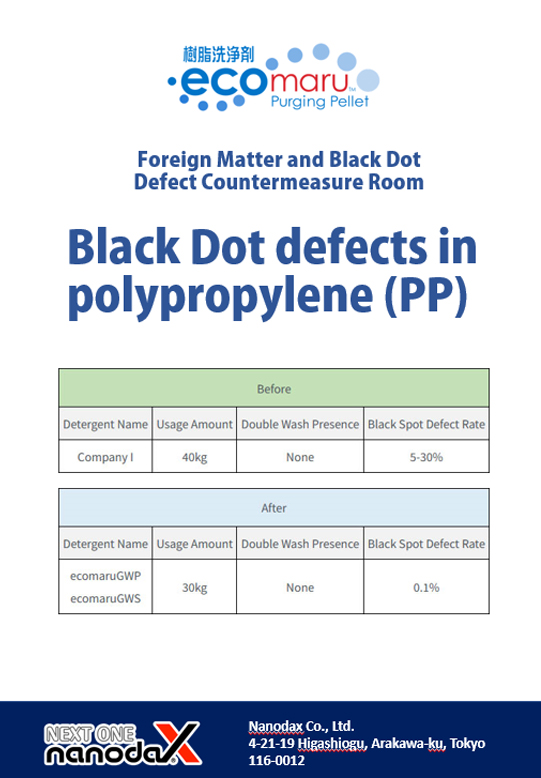

【Case 1】

- They were using a surfactant-type purging compound but couldn't prevent the occurrence of black dots. As a result, they resorted to disassembly cleaning after using the purging compound to improve the defect.

Customer evaluation

- With the adoption of ecomaru, the black dot defect rate significantly decreased, improving yield. Additionally, the effort required for disassembly cleaning was reduced, resulting in a substantial improvement in production efficiency.

- Instead of a single test with the sample, multiple tests were conducted as outlined in the ecomaru documentation. As a result, the cleaning effect became evident with each test, achieving a reduction in the defect rate.

| Customer information | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Customer name | Products manufactured | Molding machine Ton capacity | Previous resin Resin | Color | Subsequent resin Resin | Color | Challenges before introduction | ||||

| Company A | Sanitary materials | Confidential | PP | Natural | GPPS | White | Foreign Matter Defect Improvement | ||||

| Before | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Detergent Name | Usage Amount | Double Wash Presence | Black Dot Defect Rate | ||||||

| Company I | 40kg | None | 5-30% | ||||||

| After | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Detergent Name | Usage Amount | Double Wash Presence | Black Dot Defect Rate | ||||||

| ecomaruGWP ecomaruGWS | 30kg | None | 0.1% | ||||||

【Case 2】

- Machines molding PP throughout the year. They were troubled by the large amount of foreign matter generated during production startup.

Customer evaluation

- Upon switching to ecomaru and starting production, the defect rate was reduced to approximately 1%, resulting in a significant improvement in yield.

- It is used as a purging compound for thorough cleaning during production startup.

| Customer information | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Customer name | Products manufactured | Molding machine Ton capacity | Previous resin Resin | Color | Subsequent resin Resin | Color | Challenges before introduction | ||||

| Company B | Industrial machinery Parts | 100 | PP | Black | PE | Natural | Foreign Matter Defect Improvement | ||||

| Before | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Detergent Name | Usage Amount | Double Wash Presence | Black Dot Defect Rate | ||||||

| Crushed Product | Unknown | None | Non-disclosure | ||||||

| After | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Detergent Name | Usage Amount | Double Wash Presence | Black Dot Defect Rate | ||||||

| ecomaru GWP | 20kg | None | 1.00% | ||||||

【Case 3】

- The previous purging compounds had cleaning power, but it was difficult to discharge the purging compounds themselves, resulting in prolonged material changeover times.

Customer evaluation

- After testing ecomaru, the usage of purging compounds was reduced by approximately 30%. Additionally, the time required for material changeover, which had been a challenge, was reduced by about 40%, resulting in significant improvement.

- We were able to quickly transition to production, successfully reducing the costs of purging compounds and discard shots.

| Customer information | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Customer name | Products manufactured | Molding machine Ton capacity | Previous resin Resin | Color | Subsequent resin Resin | Color | Challenges before introduction | ||||

| Company C | Automotive Parts | 650~ | PP | Black | PP | White | Detergent Usage & Setup Time Reduction | ||||

| Before | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Detergent Name | Usage Amount | Double Wash Presence | Black Dot Defect Rate | ||||||

| Company R (with GF) | 300kg | None | Non-disclosure | ||||||

| After | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Detergent Name | Usage Amount | Double Wash Presence | Black Dot Defect Rate | ||||||

| ecomaru GWP | 200kg | None | Non-disclosure | ||||||

Polypropylene Characteristics

Advantages

- Lightweight: Low specific gravity (0.9)

- Superior mechanical strength (tensile strength, compressive strength, impact strength)

- High heat resistance (among thermoplastic resins)

- Excellent chemical resistance (acids and alkalis)

- Strong resistance to repeated bending (excellent hinge properties)

- Clean surface appearance: Surface is hard, smooth, and resistant to scratches

- Can produce completely glossy, colorless, transparent film

- Excellent food hygiene properties

- Good processability, compatible with various molding methods such as injection molding, extrusion, and blow molding

- Easy to mass-produce at low cost

Disadvantages

- Poor weather resistance, quickly deteriorates under direct sunlight and UV exposure

- Difficult to adhere

- Difficult to print on

Manufacturer

| Manufacturer | Product Name |

|---|---|

| Idemitsu Fine Composites | CALP |

| SABIC Japan | STAMAX Resin |

| Sun Allomer | Sun Allomer, Qualia |

| Sumitomo Chemical | Sumitomo Norbrene, Sumistran |

| Sumitomo Seika | Flobrene |

| Daicel Miraizu | Daicel PP |

| Kohroku Shoji | TR Resin |

| Terabo | Terabo Resin |

| Japan Polypropylene | Novatec PP, Wintec, Funkster |

| Prime Polymer | Prime Polypro, Mostron |

Main Applications

[Automotive Related]

Automobile bumpers and interior materials, speedometers, in-car displays, etc.

[Food Related]

Food wrap films, lunch boxes, coffee lids, bottle caps, beverage containers, convenience store food containers, trays, detergent containers, etc.

[Home Appliances Related]

Washing machines, refrigerators, televisions, smartphones, computers, etc.

[Medical Related]

Syringes, blood transfusion bags, pharmaceutical packaging, etc.

[Others]

Buckets, bath utensils, packaging films, industrial films, housing equipment, containers, daily necessities, strings, ropes, diapers, raw material fibers for carpets, underwear, and socks, etc.