Polycarbonate (PC)

Polycarbonate (PC) is a plastic material first industrially produced in 1956 by the German chemical company Bayer. It is a polymer with a carbonate ester structure in its molecular structure. It is made from bisphenol A and phosgene, or diphenyl carbonate as raw materials. PC can also be combined with materials such as ABS resin and glass fibers to create highly precise plastic materials.

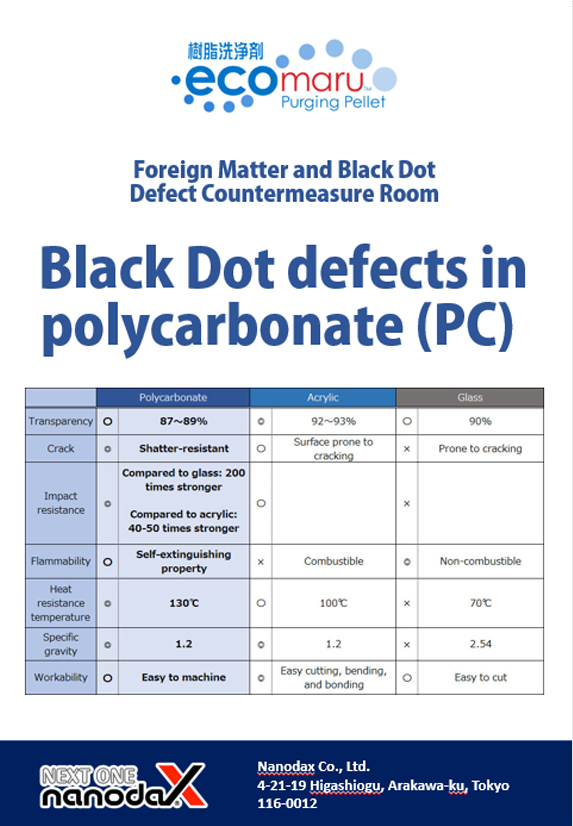

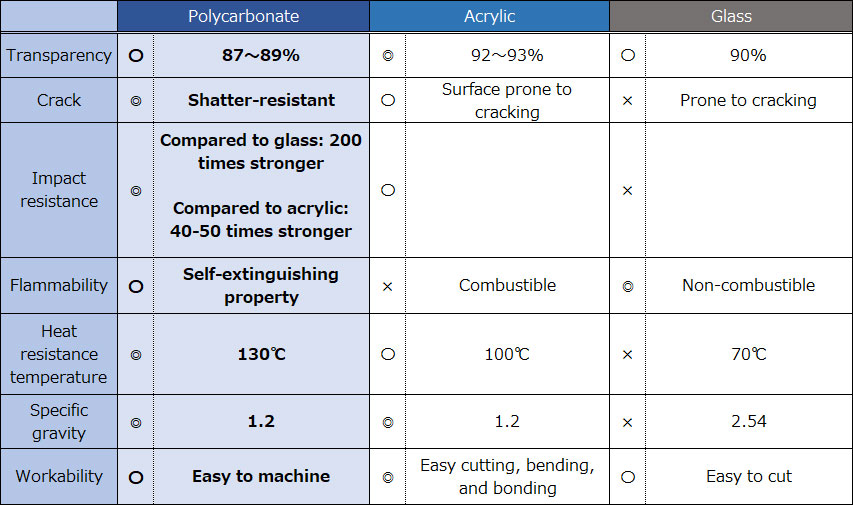

The difference between polycarbonate and acrylic

The acrylic panels that have become ubiquitous as a measure against COVID-19 are generally recognized as acrylic panels, including polycarbonate panels. However, there are differences as described below.

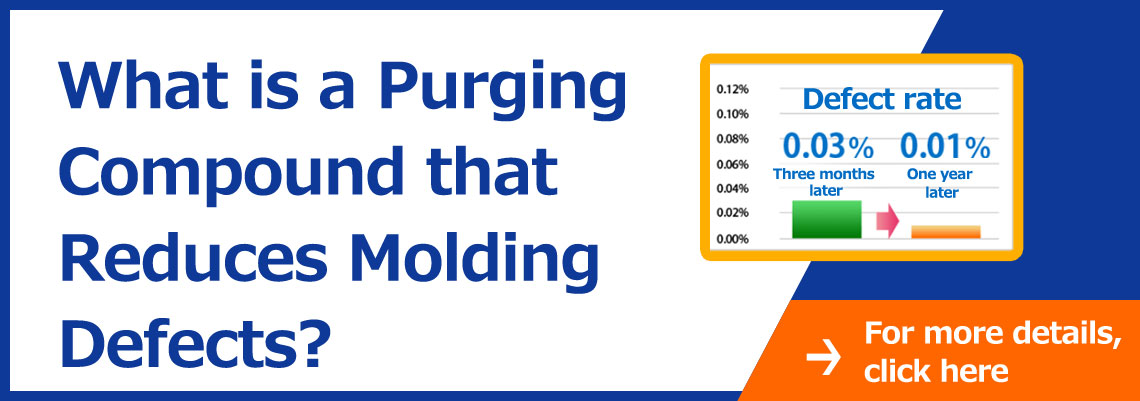

Polycarbonate black dot defect issue

Black dot defects that cannot be resolved even after cleaning, and replacement issues after cleaning. As a solution case, we will introduce an example utilizing purge agent ecomaru.

【Case 1】

- Until now, the number of foreign object contaminations has periodically increased, significantly reducing production efficiency.

Customer Evaluation

- After introducing ecomaru, the occurrence of foreign objects stopped, leading to an improvement in production efficiency.

- Compared to conventional purging compounds, the cleaning time and discharge time were reduced. Specifically, the cleaning time was reduced by an average of about 20%.

| Customer Information | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Customer Name | Product Produced | Molding Machine Tonnage | Previous Resin Resin | Color | Subsequent Resin Resin | Color | Issues Before Implementation | ||||

| Company A | Consumer Machinery Parts, etc. | 100 | PC | Black, White, etc. | PP, PA, POM | Clear, White | Improvement of Foreign Object Defects | ||||

| Before | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Purging Compound Name | Usage Amount | Whether Double Cleaning is Performed | Black Dot Defect Rate | ||||||

| Company I (With GF) | 120 | Partially Yes | Non-disclosure | ||||||

| After | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Purging Compound Name | Usage Amount | Whether Double Cleaning is Performed | Black Dot Defect Rate | ||||||

| ecomaru GWS | 100 | Partially Yes | Non-disclosure | ||||||

【Case 2】

- Purging compounds are used during production start-up. For black molded products, foreign objects can affect the shape of the molded products, making foreign object countermeasures essential.

- Until now, multiple types of purging compounds were used, and finally, double cleaning without GF was also performed, taking about 3 hours to start up.

Customer Evaluation

- ecomaru combines both cleaning and discharge properties, allowing the same defect rate to be maintained with a single cleaning.

- This reduced the amount of purging compound used by approximately half. Additionally, since the time required for a single cleaning was reduced to about one-third, significant cost savings and increased production volume were achieved.

| Customer Information | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Customer Name | Product Produced | Molding Machine Tonnage | Previous Resin Resin | Color | Subsequent Resin Resin | Color | Issues Before Implementation | ||||

| Company B | Automotive parts | Large machinery (Confidential) | PC Alloy | Black | PC Alloy | Black | Cleaning cost reduction | ||||

| Before | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Purging Compound Name | Usage Amount | Whether Double Cleaning is Performed | Black Dot Defect Rate | ||||||

| ① Company R (with GF) ② Multiple other purging compounds | Non-disclosure | Yes | 1.00% | ||||||

| After | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Purging Compound Name | Usage Amount | Whether Double Cleaning is Performed | Black Dot Defect Rate | ||||||

| ecomaru GWS | Non-disclosure | None | 1.00% | ||||||

Polycarbonate properties

Advantages

- Highly impact-resistant (the highest level among resins and plastics)

- High transparency

- Excellent dimensional accuracy

- Superior self-extinguishing properties

- Excellent weather resistance

- Resistant to high and low temperatures (wide range from -100°C to 140°C)

Disadvantages

- Weak against organic solvents and surfactants

- Easily scratched

- Prone to hydrolysis in high temperature and high humidity environments

- Deteriorates and becomes cloudy when in contact with organic coatings or adhesives

Manufacturer

| Manufacturer | Product name |

|---|---|

| Idemitsu Kosan Co., Ltd. | Taflon |

| LG | Chem |

| Kotex Co., Ltd. | Cotex |

| Covestro Japan Co., Ltd. | Apec HT / Makrolon / Bayblend |

| SABIC | LEXAN |

| Sumika Polycarbonate Ltd. | SD Polycarbonate |

| Daicel Polymer Ltd. | Novaloy X |

| Chi Mei Corp. (Chimei Industrial) | WONDERLITE |

| Teijin Limited | Panlite |

| Mitsubishi Engineering-Plastics Corporation | Iupilon / Novarex / Xantar |

Main applications

Glass fiber reinforced PC has high mechanical strength and stable electrical resistance and dielectric constant, making it widely used in electrical and electronic applications, among others.

【Electrical and Electronics】

LCD panel components, connectors, relay parts, telephone parts, TV parts, smartphone bodies, PC bodies

【Construction】

Carports, terraces, sports facilities, arcades, partitions, screens, displays, lighting covers

【Others】

Eyeglasses and sunglasses, goggles, lighting lenses, helmets, car headlight covers, airplane and fighter jet windows, etc.