What is PBT (polybutylene terephthalate)?

Commonly referred to as PBT, polybutylene terephthalate is a type of polyester and a thermoplastic crystalline engineering plastic. It is made by polycondensation of terephthalic acid or dimethyl terephthalate with 1,4-butanediol. By the way, PET in PET bottles (polyethylene terephthalate) is produced from ethylene glycol and terephthalic acid. PBT is generated by using 1,4-butanediol instead of ethylene glycol found in PET.

PBT combines excellent properties such as electrical characteristics, chemical resistance, and heat resistance with good processability, and it strikes a balance with its cost, making it the most demanded engineering plastic. Its most notable feature is that it can be reinforced by combining it with other materials such as glass fiber. Glass fiber-reinforced PBT, which is commonly used, offers enhanced mechanical properties and excels in wear resistance, heat resistance, and electrical properties.

Black Dot Defect Issues in PBT

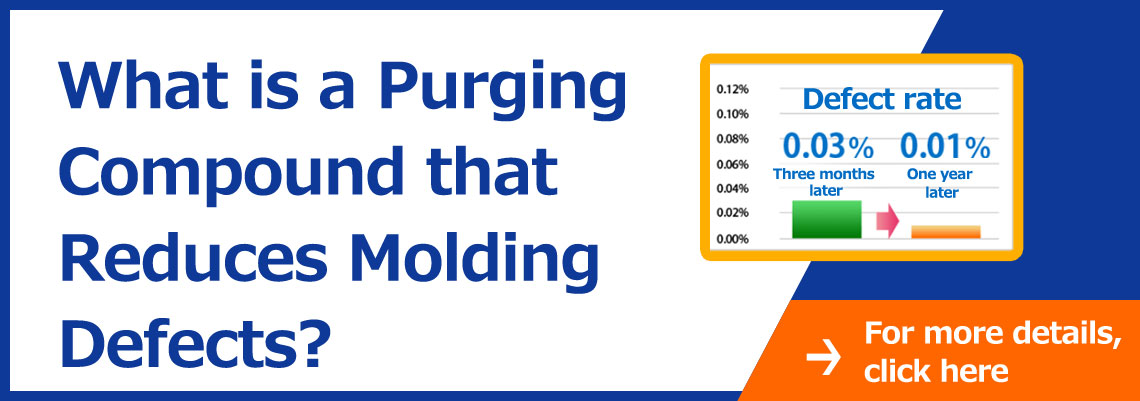

PBT resin has many flame retardant grades from various manufacturers. In molding sites, we often hear that flame retardant additives tend to cause burning and carbide formation. Previously, we mentioned that the flame retardant function can simultaneously cause black dot defects. Many molding sites have expressed concerns about black dot defects. They want to improve the defect rate and reduce the number of cleaning cycles. As a result of trying purge agent ecomaru based on these requests, we will introduce a case that led to improvement.

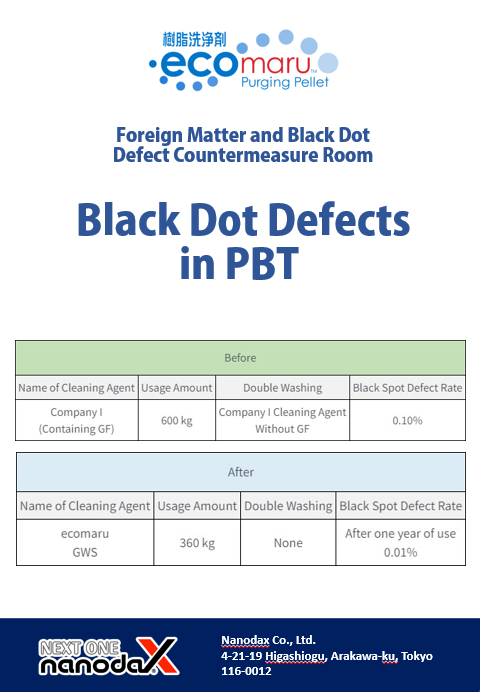

【Case 1】

- 【Reduction of Foreign Matter Defects】Reducing the current defect rate of 0.1% to nearly zero

Customer Evaluation

- Successfully improved the amount of purging compound used and defect rate, achieving significant total cost reduction.

- Increased production time led to improved productivity!

| Customer Information | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Customer Name | Products Produced | Molding Machine Ton Capacity | Previous Resin Resin | Color | Subsequent Resin Resin | Color | |||||

| Company A | Home appliance parts | 350 | PBTGF Flame-retardant | Brown | PBTGF Flame-retardant | White | |||||

| Before | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Name of Purging Compound | Usage Amount | Double Washing | Black Dot Defect Rate | ||||||

| Company I (Containing GF) | 600 kg | Company I Purging Compound Without GF | 0.10% | ||||||

| After | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Name of Purging Compound | Usage Amount | Double Washing | Black Dot Defect Rate | ||||||

| ecomaru GWS | 360 kg | None | After one year of use 0.01% | ||||||

【Case 2】

- Defects due to foreign matter contamination are occurring frequently.

- During molding, the color of the previous material frequently mixes in, forcing production to stop each time.

Customer Evaluation

- The amount and frequency of detergent usage (number of washes) have not changed, but whereas the conventional defect rate was gradually increasing, after switching to the purge agent ecomaru, the defect rate stabilized and remained consistent.

- The color of the previous material no longer mixes in, eliminating the need to stop production. As a result, productivity has significantly improved.

| Customer Information | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Customer Name | Production Item | Molding Machine Tonnage | Previous Resin Resin | Color | Subsequent Resin Resin | Color | |||||

| Company B | Factory Equipment Parts | 220 | PBT | Black | PA | White | |||||

| Before | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Detergent Name | Usage Amount | Double Wash: Yes/No | Black Dot Defect Rate | ||||||

| Company R (with GF) | Non-disclosure | Yes | Non-disclosure | ||||||

| After | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Name of Purging Compound | Usage Amount | Double wash presence | Black Dot defect rate | ||||||

| ecomaru GWS | Non-disclosure Use the same amount as before | Present | Non-disclosure Significantly reduced compared to Before | ||||||

PBT characteristics

Advantages

- Excellent mechanical properties

- Excellent friction and heat resistance

- Excellent electrical properties

- Excellent oil resistance, solvent resistance, and chemical resistance

- Excellent moldability

- Low water absorption and good dimensional stability

- Excellent surface gloss and good colorability

Disadvantages

- Weak against strong alkalis and phenols

- Hydrolyzes

Manufacturer

| Manufacturer | Product name |

|---|---|

| SABIC Japan LLC | VALOX |

| CHIMEI Corporation | CCP PBT |

| DuPont Co., Ltd. | Crastin |

| Teijin DuPont Films Japan Co., Ltd. | Terrabo Resin |

| Toyobo Co., Ltd. | PLANAC |

| Toray Industries, Inc. | TORELON |

| BASF Japan Ltd. | Ultradur |

| Polyplastics Co., Ltd. | Duranex, Duranex-EX |

| Panasonic Corporation | Fullfine |

| Mitsubishi Engineering-Plastics Corporation | NOVADURAN |

| LANXESS K.K. | Pocan |

Main Applications

Glass fiber reinforced PBT is widely used in various applications, including electrical and electronic uses, due to its high mechanical strength and stable electrical resistance and dielectric constant.

【Electrical and Electronic】

Drive housings for copiers, cooling fans, sockets, and power connectors

【Automotive】

Door mirrors, door grips, wire harness connectors, airbag electrical components, wiper parts, exhaust gas control valves, light components

【Others】

Keyboard keys, fishing gear, precision machinery parts, watch components, etc.